Recently, Xcel Energy, a large energy company in the United States, selected portable actuators as a tool to combat fatigue in manual valve operations. The decision to use Sofis portable actuators was based on an evaluation carried out by a committee of engineers, ergonomic specialists, and operators to address operational,... read more →

Aug

08

Aug

08

In the pursuit of cleaner and sustainable energy solutions, hydrogen has emerged as a promising fuel. Sofis’ primary objective is to ensure safety in the hydrogen economy given the inherent dangers it presents, and one of these applications identified is the hydrogen offloading process. A Sofis customer recently implemented a... read more →

Aug

07

With the growing demand for renewable energy sources, offshore wind farms have become a prominent solution. Offshore wind HVDC converter platforms play a crucial role in transmitting this clean energy to the onshore grid. However, the proper functioning of these platforms relies on various critical systems, including cooling medium expansion... read more →

Jul

04

LOPA, or Layers of Protection Analysis, is developed on the basis of a risk identification analysis (like HAZOP). LOPA identifies the countermeasures available against the potential consequences of a particular risk. Starting from the quantification of the likelihood of a particular hazard, LOPA analyses the system and identifies the mitigation... read more →

May

15

To help guide the rapid expansion of Sofis in the Americas, Cesar Perez has joined Sofis since August 2022. As a Service Technician, he is responsible for precisely installing and accurately maintaining Sofis products, and he will gradually help train future colleagues. Before joining Sofis, Cesar was employed as a... read more →

Apr

10

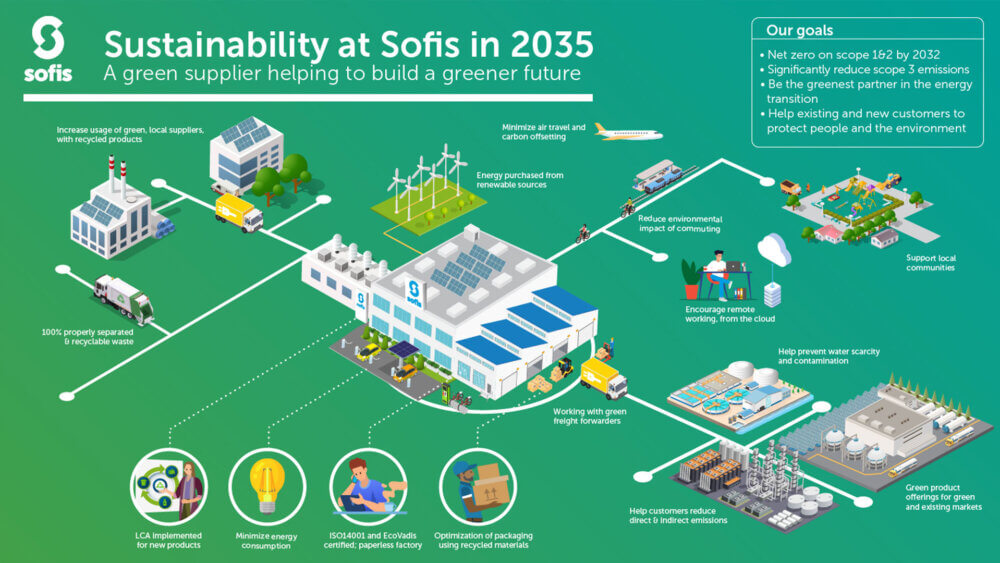

On our journey to become more sustainable, we have set exciting and ambitious targets: Our current products and solutions are installed all over the world, protecting people and the environment. We will continue to focus on developing new solutions that ensure safety for people and safety for the environment. Our... read more →

Mar

29

Since January 2023, Linda Schulte is Sofis' new Commercial Director. With a long track record in sales and marketing in both industrial as well as consumer markets, she is determined to put Sofis' customers first. Back in 2022, Linda was approached on LinkedIn by recruitment specialist SolutionsDriven, who introduced her... read more →

Mar

27

Pipeline pigging is a high risk event with people involved on the spot. At the same time, safe operation depends on these people. Essential process Pigging procedures are used in pipeline maintenance to remove debris, scale, and other deposits that can accumulate inside the pipeline. Pipeline pigging is an essential... read more →

Mar

08

Trinseo is a specialty material solutions provider. A great example of an end-product that is made from Trinseo’s plastics is Lego. To operate manual valves safely and efficiently, Trinseo staff uses the Power Wrench portable actuator. The portable actuator is used during the production process of Ethylbenzene, Styrene, LATEX, ABS,... read more →

Mar

08

The ageing of oil and gas production platforms, pipelines, refineries, and petrochemical plants can pose a range of challenges and risks. Equipment and infrastructure that are past their design life are more likely to experience failures, which can result in unplanned downtime, loss of production, and potentially hazardous situations leading... read more →